HDPE Fittings Manufacturers In Vadodara, Gujarat

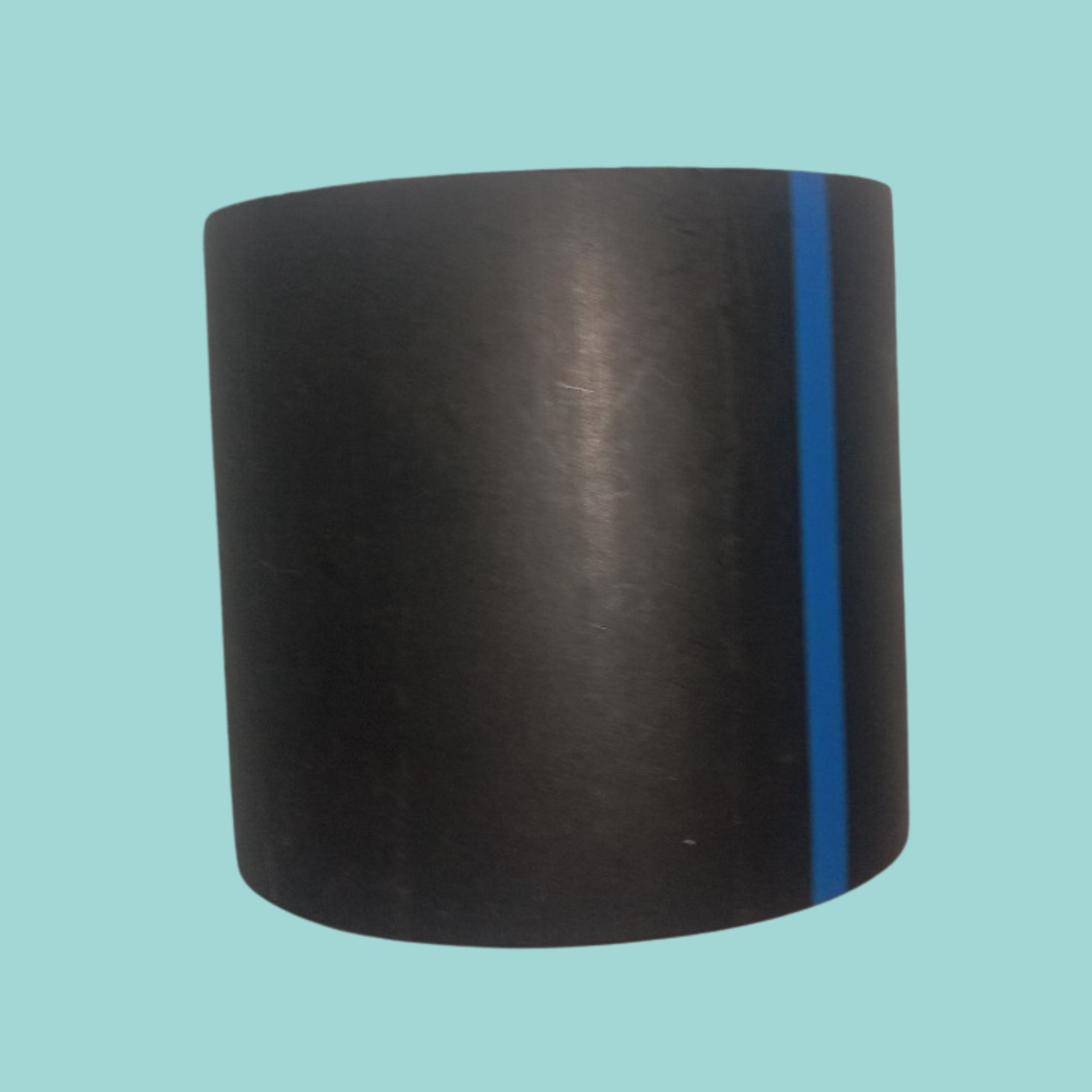

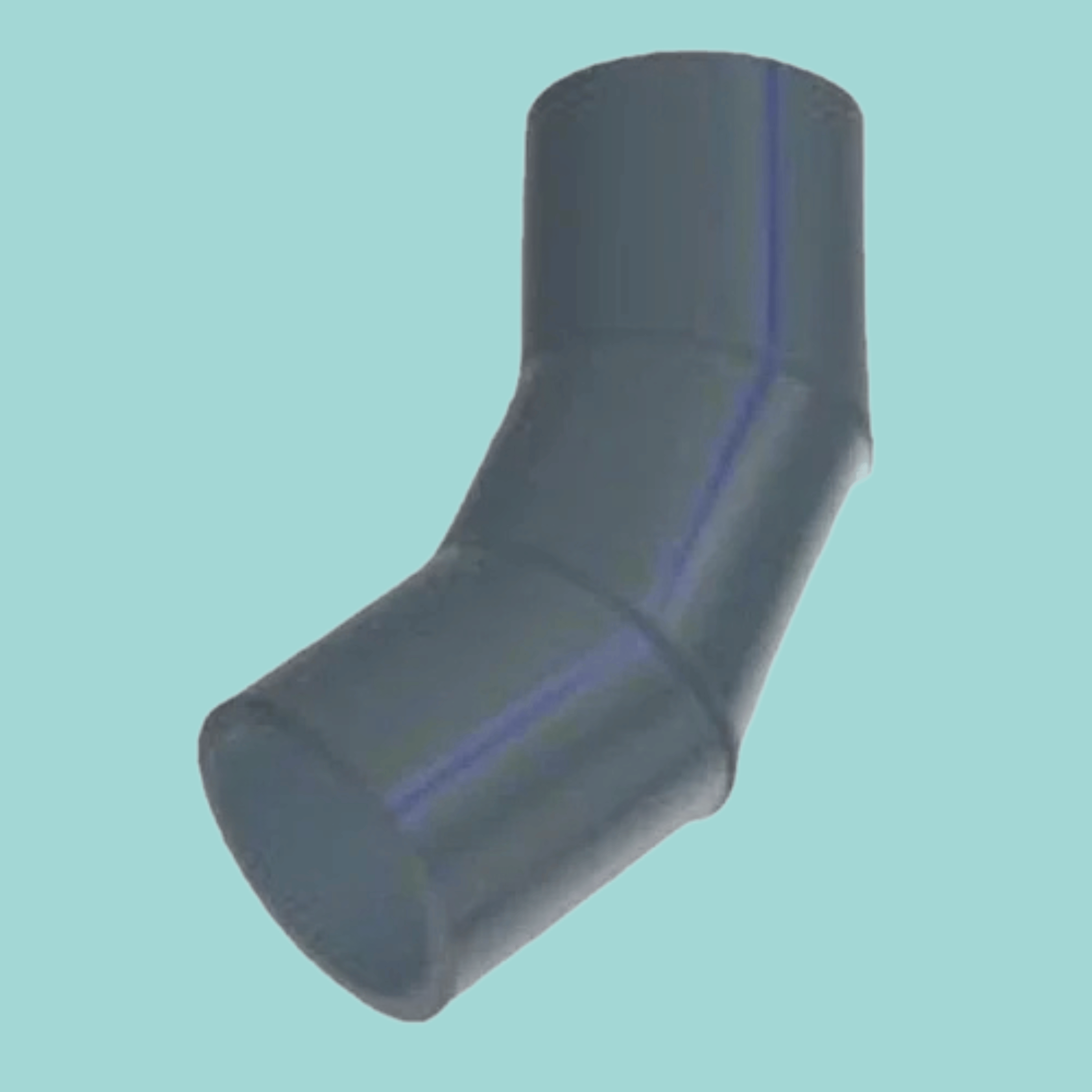

HDPE Fittings

Product Overview

HDPE (High-Density Polyethylene) pipe fittings are accessories used to connect, branch, terminate, or redirect sections of HDPE pipe. They create durable, leak-proof joints in piping systems for a wide range of applications, including water supply, gas distribution, and industrial fluids.

Key Features

- Corrosion and chemical resistance

- Flexibility

- Durability and longevity

- Lightweight

- Leak-free joints

Applications

HDPE fittings are used in a variety of industries for many fluid and gas transport applications.

Water distribution

Municipal, industrial, and residential water supply systems.

Gas distribution

Natural gas and other fuel gas pipelines.

Mining

Transporting slurry and other industrial fluids.

Agriculture

Irrigation systems, including sprinkler and drip systems.

Sewerage and drainage

Sanitary and industrial sewage systems.

Telecommunications

Cable and conduit protection.

Product Range

We offer a comprehensive range of HDPE fittings in various sizes, pressure ratings, and configurations to meet diverse application requirements.

| Product Type | Size Range (mm) | Pressure Rating (PN) | Material Grade |

|---|---|---|---|

| Elbows (45°, 90°) | 20 - 800 | PN6 - PN16 | PE80, PE100 |

| Tees (Equal, Reducing) | 20 - 630 | PN6 - PN16 | PE80, PE100 |

| Reducers | 25 - 500 | PN6 - PN16 | PE80, PE100 |

| End Caps | 20 - 800 | PN6 - PN16 | PE80, PE100 |

| Couplings | 20 - 800 | PN6 - PN16 | PE80, PE100 |

| Flange Adaptors | 40 - 800 | PN6 - PN16 | PE80, PE100 |

| Electrofusion Fittings | 20 - 315 | PN10 - PN16 | PE80, PE100 |

Technical Information

Our HDPE fittings are manufactured in compliance with international standards including ISO 4427, ASTM D3350, and EN 12201. They are designed to withstand demanding operating conditions while maintaining structural integrity.

The fittings are available in both black and natural (white) colors, with UV-stabilized options for above-ground applications. All products undergo rigorous quality control testing to ensure consistent performance.

For specific technical data sheets, installation guidelines, or custom requirements, please contact our technical support team.

| Property | Value | Test Standard |

|---|---|---|

| Density | 0.941 - 0.965 g/cm³ | ISO 1183 |

| Melt Flow Index | 0.1 - 1.0 g/10 min | ISO 1133 |

| Tensile Strength | 20 - 30 MPa | ISO 527 |

| Elongation at Break | > 600% | ISO 527 |

| Hydrostatic Strength | > 8.0 MPa | ISO 1167 |

| Operating Temperature | -40°C to +60°C | - |

Our HDPE Fittings Products

Frequently Asked Questions

PE80 and PE100 refer to the Minimum Required Strength (MRS) of the polyethylene material. PE80 has an MRS of 8.0 MPa, while PE100 has an MRS of 10.0 MPa. PE100 offers higher pressure resistance and allows for thinner pipe walls at the same pressure rating, making it more efficient for high-pressure applications.

HDPE fittings can be joined using several methods: butt fusion (for pipes of the same diameter), socket fusion (for smaller diameters), electrofusion (using special fittings with integrated heating elements), and mechanical connections (for temporary or transition connections to other materials).

Yes, our HDPE fittings are manufactured from materials that comply with international standards for potable water contact, including NSF/ANSI 61, WRAS, and KTW. They do not leach harmful substances and maintain water quality throughout their service life.

When properly installed and operated within design parameters, HDPE fittings have a service life exceeding 50 years. Their resistance to corrosion, chemical attack, and environmental stress cracking contributes to this exceptional longevity.

Yes, we offer HDPE fittings specifically designed and certified for gas distribution applications. These fittings comply with relevant gas industry standards and are manufactured with additional quality controls to ensure safety in gas service.

Yes, we can manufacture custom HDPE fittings to meet specific project requirements. This includes non-standard sizes, special configurations, or fittings with specific material properties. Please contact our technical team with your requirements for a custom solution.