PVDF Fittings Manufacturers And Supplier In Vadodara, Gujarat

PVDF Fittings

Product Overview

PVDF (Polyvinylidene Fluoride) is a high-performance thermoplastic fluoropolymer known for its excellent chemical resistance, high purity, and superior mechanical strength. It is widely used in corrosive and high-purity fluid handling systems, particularly in the chemical, pharmaceutical, and semiconductor industries.

Key Features

- Outstanding chemical and corrosion resistance

- Continuous service temperature range: -40°C to +140°C

- High mechanical strength and rigidity

- Excellent UV and weather resistance

- Non-toxic, FDA approved, and suitable for high-purity applications

- Low permeability and leakage prevention

- Smooth internal surface reduces friction and prevents scaling

- Non-flammable with high Limiting Oxygen Index (LOI)

Applications

PVDF fittings are ideal for aggressive and high-purity environments, offering unmatched reliability across various industrial sectors.

Chemical Processing

Used for transporting corrosive acids (HCl, H₂SO₄, HF), alkalis, and solvents safely and efficiently.

Pharmaceutical & Biotech

Ideal for high-purity fluid handling, sterile water systems, and DI/WFI applications.

Semiconductor Industry

Used in ultrapure water (UPW) and chemical delivery systems due to its cleanliness and stability.

Water Treatment

Perfect for chlorination systems, demineralized water pipelines, and wastewater management.

Food & Beverage

Used in process fluid conveyance and cleaning systems; FDA-compliant and non-toxic.

Oil & Gas

For transporting corrosive hydrocarbons and chemical injections in harsh environments.

Electroplating & Metal Finishing

Handles acidic and alkaline solutions in electroplating baths and metal surface treatments.

Nuclear Industry

Used in systems requiring radiation resistance and chemical stability.

Product Range

We offer a comprehensive range of PVDF fittings that meet demanding industrial and laboratory applications.

| Product Type | Size Range (mm) | Pressure Rating (PN) | Material Grade |

|---|---|---|---|

| Elbows (45°, 90°) | 20 - 110 | PN10 - PN16 | PVDF ASTM D3222 |

| Tees (Equal, Reducing) | 20 - 110 | PN10 - PN16 | PVDF ASTM D3222 |

| Couplers & Unions | 20 - 110 | PN10 - PN16 | PVDF ASTM D3222 |

| Valves (Ball, Diaphragm, Check) | 20 - 90 | PN10 - PN16 | PVDF ASTM D3222 |

| End Caps & Bushings | 20 - 110 | PN10 - PN16 | PVDF ASTM D3222 |

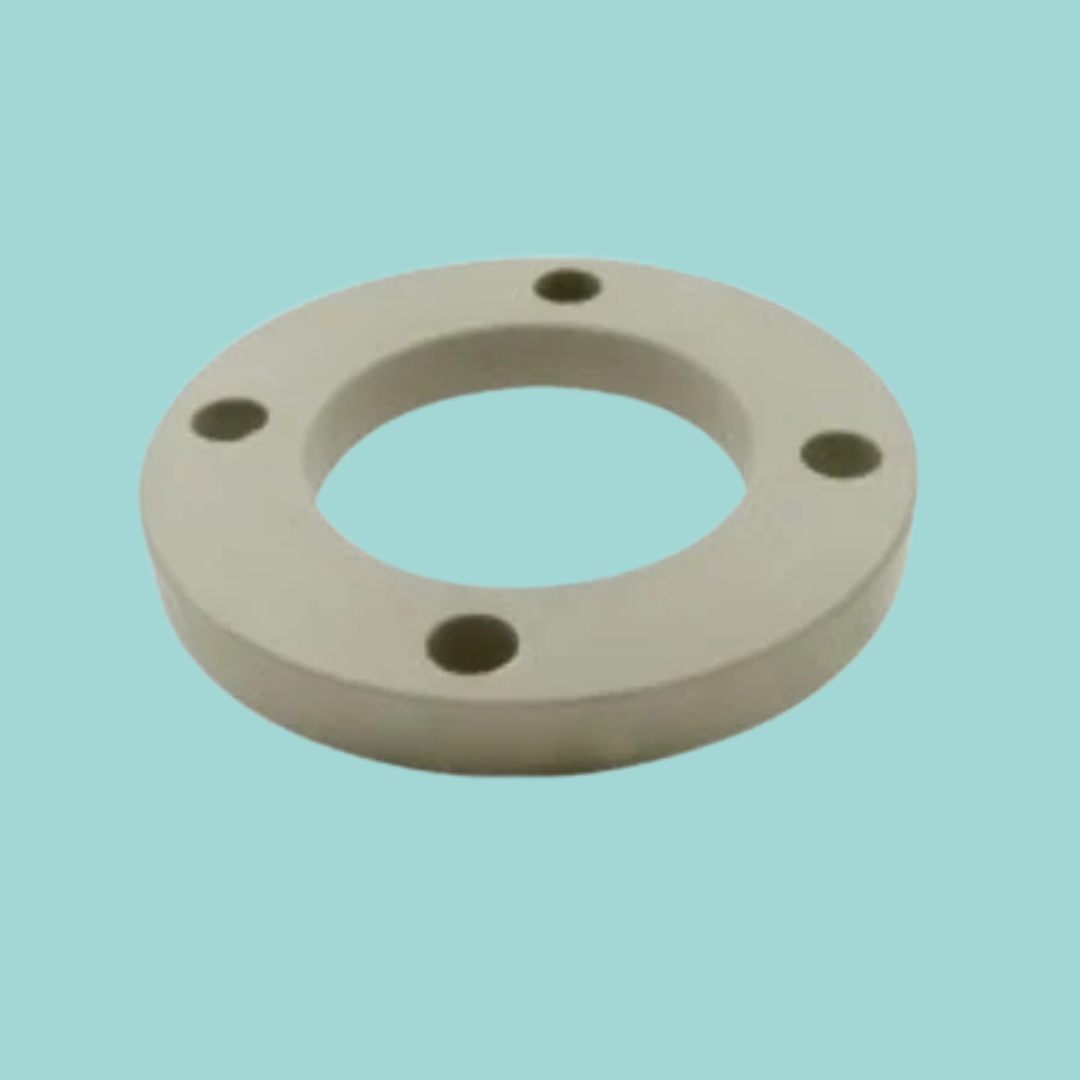

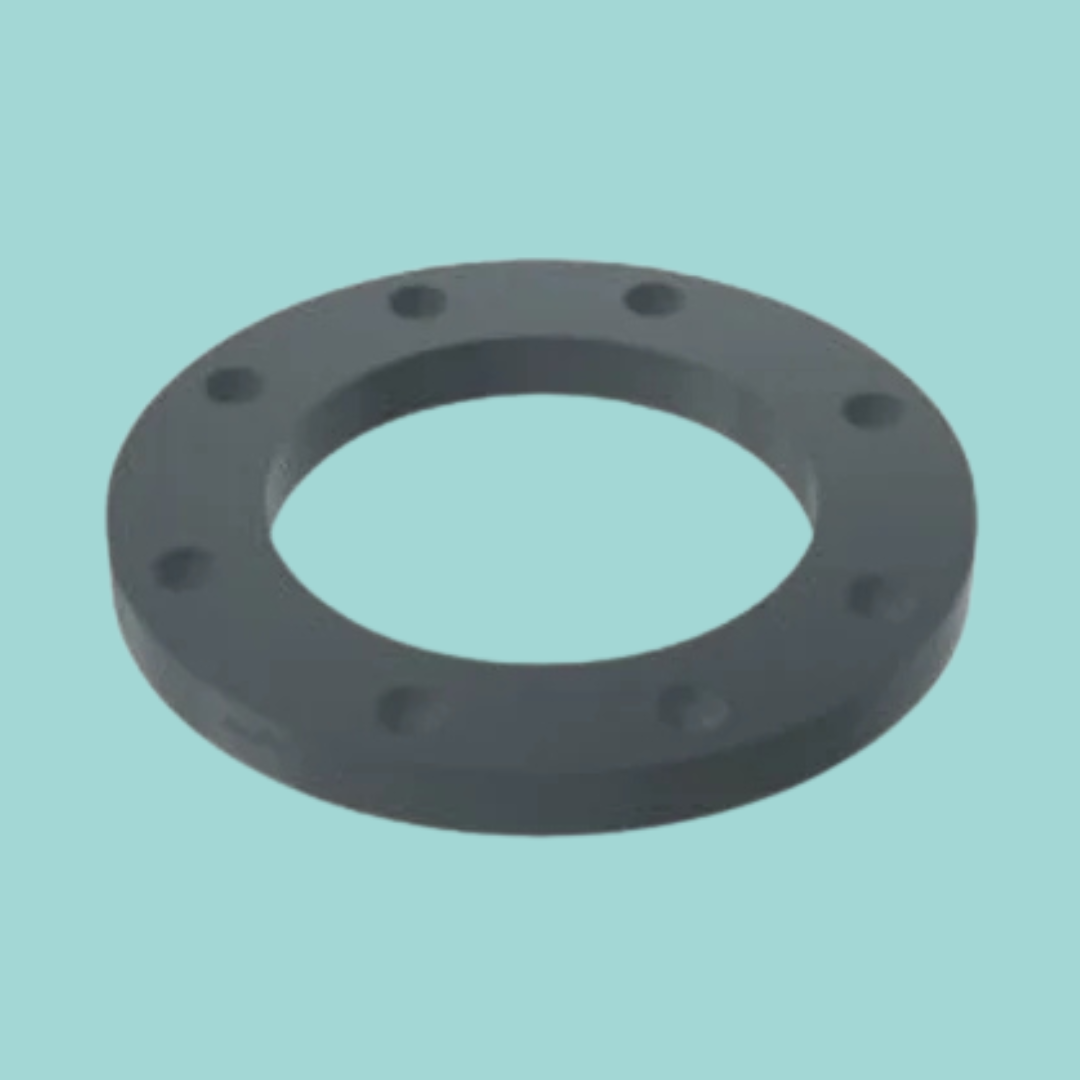

| Flanges & Inserts | 32 - 160 | PN10 - PN16 | PVDF ASTM D3222 |

Technical Information

PVDF fittings meet ASTM D3222 and ISO 10931 standards, ensuring superior physical, chemical, and thermal performance.

| Property | Value | Test Standard |

|---|---|---|

| Density | 1.78 g/cm³ | ISO 1183 |

| Melting Point | 165 - 175°C | ISO 11357 |

| Tensile Strength | 50 - 60 MPa | ISO 527 |

| Elongation at Break | 20 - 50% | ISO 527 |

| Thermal Conductivity | 0.19 W/m·K | DIN 52612 |

| Operating Temperature | -40°C to +140°C | - |

Our HDPE Fittings Products

Frequently Asked Questions

PVDF fittings can operate continuously between -40°C and +140°C, suitable for hot and cold chemical systems.

Yes, they are resistant to most acids, bases, halogens, and solvents, ideal for aggressive chemical handling.

Absolutely. PVDF is non-toxic, FDA approved, and safe for food, water, and pharmaceutical applications.

Yes, PVDF has excellent weather and UV resistance, suitable for both indoor and outdoor installations.

PVDF fittings offer a service life exceeding 25 years under continuous use in harsh conditions.