PPH Fittings Manufacturers In Vadodara, Gujarat

PP & PPH Fittings

Product Overview

PPH (Polypropylene Homopolymer) pipe fittings are components made from a thermoplastic polymer known for its excellent chemical resistance, high stiffness, and thermal stability. These fittings are used to create durable, leak-proof connections in piping systems, particularly in industrial environments where chemical and heat resistance are critical.

Key Characteristics of PPH Fittings

- Excellent chemical resistance to acids and alkalis

- High temperature stability

- Low thermal expansion

- High tensile and mechanical strength

- Good weldability and easy fabrication

- Non-toxic and non-corrosive

Applications

PPH fittings are widely used in demanding industrial applications where chemical resistance and heat performance are crucial.

Chemical Processing

Used in transporting corrosive and abrasive fluids in chemical and pickling plants.

Water Treatment

Ideal for piping systems in water and wastewater treatment facilities.

Pharmaceutical & Food Industries

Suitable for processes requiring sanitary, non-toxic, and chemical-resistant materials.

Nuclear Research

Used in labs and plants where high purity and resistance to chemicals are mandatory.

Metallurgy

Common in tanks and linings for metal extraction and processing applications.

Industrial Plants

Used in industrial fluid transport, drainage, and venting applications.

Product Range

We offer a comprehensive range of PP and PPH fittings in various sizes, pressure ratings, and configurations suitable for all kinds of industrial and chemical piping requirements.

| Product Type | Size Range (mm) | Pressure Rating (PN) | Material Grade |

|---|---|---|---|

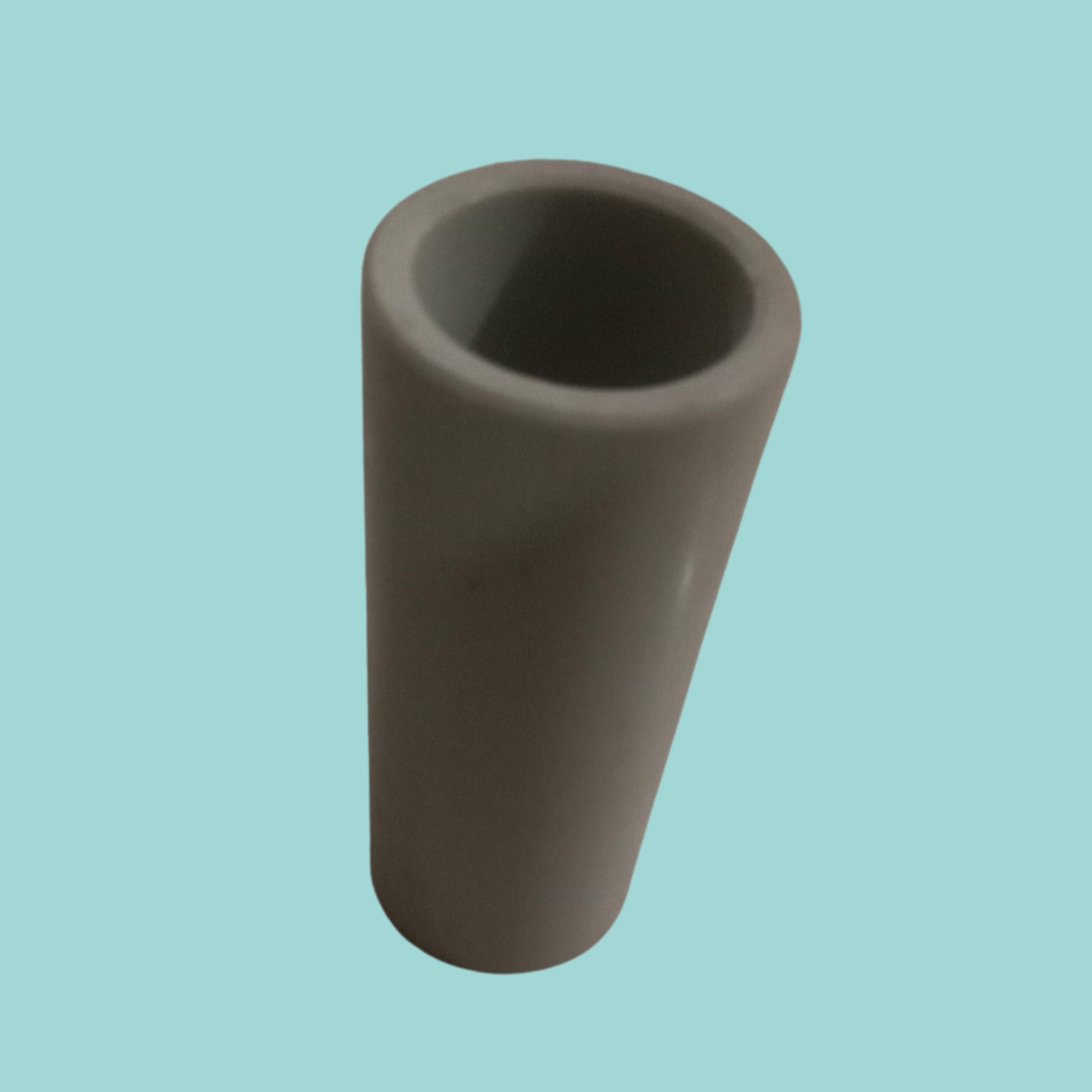

| Elbows (45°, 90°) | 20 - 400 | PN6 - PN16 | PP-H, PP-R |

| Tees (Equal, Reducing) | 20 - 355 | PN6 - PN16 | PP-H |

| Reducers (Concentric / Eccentric) | 25 - 315 | PN6 - PN16 | PP-H |

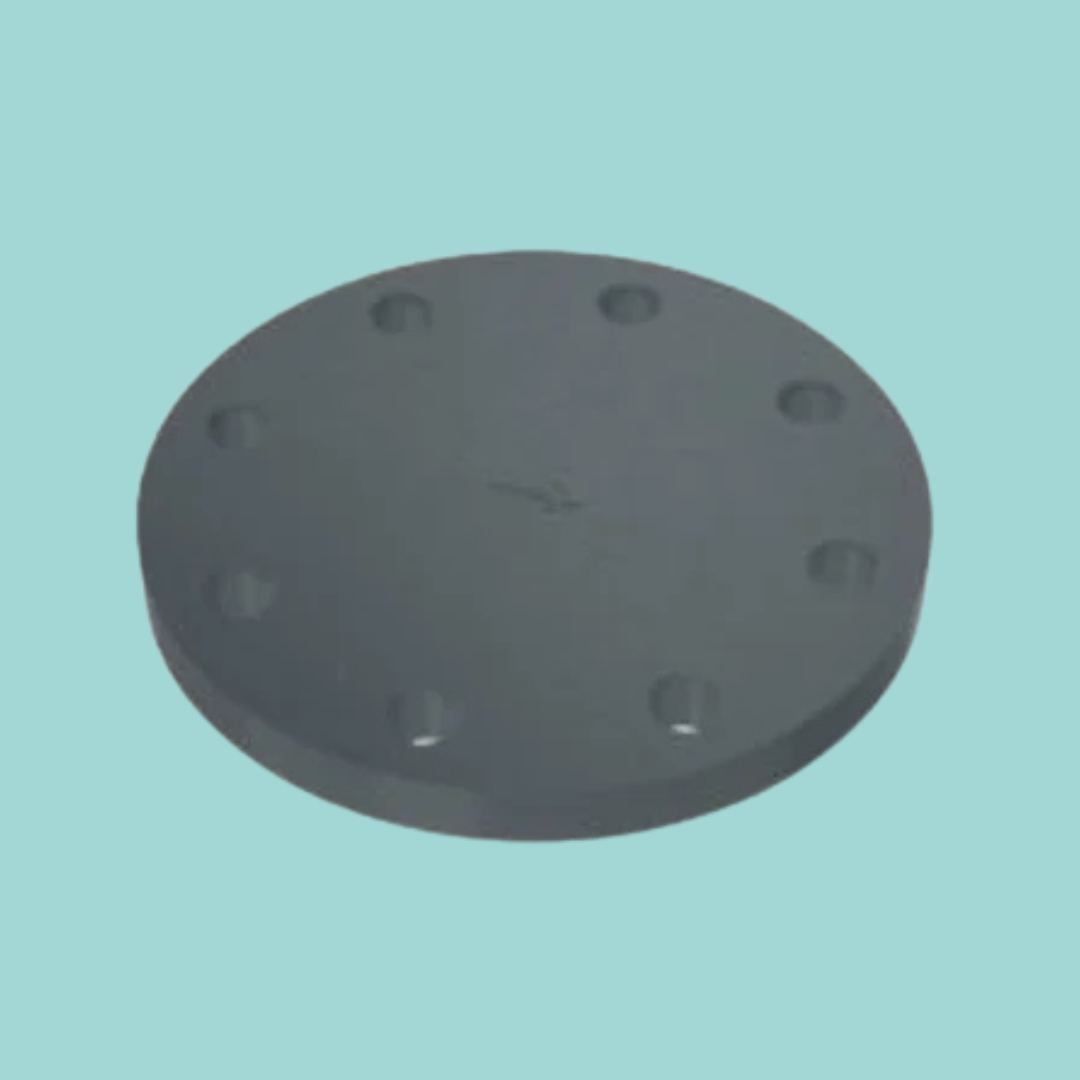

| End Caps | 20 - 400 | PN6 - PN16 | PP-H |

| Flange Adaptors | 40 - 400 | PN6 - PN16 | PP-H |

| Valves (Ball, Diaphragm) | 20 - 315 | PN10 - PN16 | PP-H |

Technical Information

Our PP & PPH fittings are manufactured to international standards such as DIN 8077/8078 and ISO 15494. They exhibit excellent mechanical strength and chemical stability across a wide range of temperatures.

| Property | Value | Test Standard |

|---|---|---|

| Density | 0.905 g/cm³ | ISO 1183 |

| Melting Point | 160 - 165°C | ISO 11357 |

| Tensile Strength | 32 MPa | ISO 527 |

| Elongation at Break | ~50% | ISO 527 |

| Thermal Conductivity | 0.22 W/m·K | DIN 52612 |

| Working Temperature | 0°C to +90°C | - |

Our HDPE Fittings Products

Frequently Asked Questions

PPH (Polypropylene Homopolymer) is more rigid and has better chemical resistance and heat stability than standard PP. It is preferred for chemical, industrial, and high-temperature applications.

Yes. PPH fittings can handle hot fluids up to 90°C continuously, making them ideal for industrial hot water systems but not suitable for high-pressure steam lines.

Absolutely. PPH fittings can be joined by butt fusion, socket fusion, or electrofusion methods ensuring leak-free joints and high mechanical strength.

Yes. PPH pipes and fittings are non-toxic, corrosion-free, and compliant with hygienic standards suitable for potable and process water applications.

Yes, PPH exhibits superior chemical resistance to most acids, bases, and organic solvents, making it perfect for chemical transport and storage systems.